| |

TRANSONITE Sandwich Panels

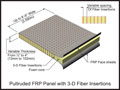

TRANSONITE™ is the culmination of many years of R&D, first conceived from a grant through the National Institute for Science and Technology (NIST), Advanced Technology Program (ATP).  | TRANSONITE Specifications Advanced proprietary FRP pultruded sandwich panels utilizing 3-dimensional skin connecting fibers. Product Range | Parameter | Minimum | Maximum | | Width | 6 inches | 102 inches | | Length | 1 inch | UNLIMITED | Facing Thickness | 0.050 inches | 0.5 inches | | Sandwich Thickness | 0.5 inches | 4 inches | | 3D Fiber Density | 1/2 per sq inch | 16 per square inch | TRANSONITE™ is a customized product designed for the end use. The core material may vary (foam, balsa, phenolic, etc.), and a wide range of fibers, fabrics, and resins can be utilized for the composite skin. The overall thickness can vary up to 4 inches. Individual skin thickness may vary, and the density of 3-D fibers is adjustable. This creates the ideal sandwich panel that can meet all strength, weight, and cost demands - regardless of the application. | | | |  | Benefits The 3-D through-thickness fibers in TRANSONITE™ provide greater durability than conventional sandwich panels. Delamination, a common problem in traditional sandwich materials, is virtually eliminated with the 3-D reinforcements that tie the face sheets together. Additionally, TRANSONITE™ is one of the only panel products available which can be produced at any length, and width up to 8.5 feet. This provides large clean surfaces with no edges or seams. TRANSONITE™ can be manufactured using a wide variety of core materials, reinforcements, fabrics, and resins. TRANSONITE™ Delivers: - Extremely High Strength

- Very Lightweight

- Corrosion Resistance

- Extreme Durability

- Large Panel Size

- Acoustic Dampening

- Insulative Properties

- High Volume Production

- Fire Resistant Properties

- Low Cost

| | | |  | Applications TRANSONITE™ is ideal for many different applications due to the wide array of benefits it can provide. A few of the applicable industries are listed below: - Bar Stock

- Aerospace

- Air Cargo Containers

- Automotive

- Furniture

- Lumber Replacement

- Recreational Equipment

| - Ballistic Panels

- Truck Trailers

- Marine

- Air Matting

- Rail Cars

- Bridge Decks

- Industrial Mats

| | | | |  | TRANSONITE Solid Plate TRANSONITE™ Bar Stock is as strong as steel yet lighter. It can be pultruded up to 1 inch think, up to 8 feet wide, and at any length required. Bar Stock made with the TRANSONITE™ process, contains structural fibers spanning three orthogonal directions. This solid composite is ideal for machining small components, as it is quasi-isotropic. This Bar Stock is ideal for use in corrosive and marine industries, and can easily be fabricated with CNC equipment using diamond tools or water jet. Additionally, because it has 3-D fibers, machined components hold together. | | | |  | Licensing Opportunities Currently TRANSONITE™ materials are manufactured by Ebert Composites and by Creative Pultrusions, Inc. (CPI), under a license agreement. | | | | | | TRANSONITE™ is a registered trademark and is manufactured under one or more of the following U.S. Patents: #7,056,576, #7,217,453, #7,785,693, #7,846,528, #7,387,147, #6,676,785, #6,645,333, #7,105,071, and #8,002,919. | | |